Linear actuators are designed to initiate precision movements in applications where lifting, pushing, pulling, sliding, and tilting of a load happens. The actuation in these actuators may be created through electrical, electrohydraulic, hydraulic, and pneumatic designs. Electric linear actuators are the most popular linear actuator types and are fitted with DC or AC motors. These actuators are fitted with acme lead screws or ball screws, which can control their motion while extending or retracting. We, at Venture Manufacturing, provide a comprehensive range of linear motion actuators in 12-120V configurations in different stroke lengths, capacities, and speeds. All our linear actuators including electric linear actuators and various types of industrial linear actuators can be customized to meet your specific requirements. Contact us today to build a perfect linear actuator for your standard or special motion needs.

Types of Linear Actuators for Reliable Applications and Durable Performance

We provide linear motion actuators in various voltage options, such as 12V, 24V, 36V, 48V, 90V, and 120V to move a wide range of static and dynamic loads. Every linear actuator displayed here is stringently tested before leaving our facility.

Heavy Duty Linear Actuators

-

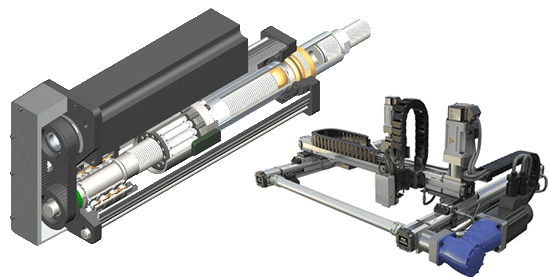

Ball Screw Actuator Design

-

Efficiency in Terms of Position Accuracy

High Speed Linear Actuators

-

Sleek & Compact Design

-

Excellent Load Bearing Capacity

Industrial Linear Actuators

-

Lift Thousands of Pounds of Force

-

Used in Extreme Temperatures

Motorized Linear Actuators

-

Designed with AC and DC Motors

-

Integrated Adjustable Limit Switches

Electromechanical Linear Actuators

-

Simple Installation

-

Weather Resistant Sealant

Why is Venture Manufacturing the Most Trusted Brand for Industrial Linear Actuators?

Over the years, we have emerged as one of the leading linear actuator manufacturers in the US. Our industrial linear actuators have been successfully deployed in critical applications across healthcare, military and defense, automation, and automotive industries. Our commitment to quality and expertise in engineering and technology has helped us offer quality linear motion actuation solutions. The following features of our services have contributed to our growth as one of the most trusted linear actuator manufacturers in the US.

-

Quality Assurance: Venture Manufacturing is an ISO 9001:2015 compliant organization. This compliance shows our commitment to quality and assures continuous improvement in processes and products.

-

Extensive Testing Capabilities: All our industrial linear actuators are extensively tested in simulated environments to ensure their performance in real environments. The testing procedures are designed to test actuators according to their operating environment.

o Ingress Protection Testing

o Shock Testing

o Mechanical Durability Testing

o Chemical Testing

o Temperature and Humidity Testing

-

Excellent Mobility: Precision motion is an important requirement in various industrial applications. Our electric linear actuators feature in-line, parallel or right angle DC motors that enable smooth linear motion in all environments. Our selections also feature high-speed linear actuators that can be fitted with potentiometers, reed sensors, hall effects or encoders for precise feedback of movements.

-

Compact Designs: Our selection features several slim actuators that are designed for applications where size, power, and speed matter, such as medical and healthcare applications. These electric linear actuators are equipped with powerful DC motors in voltages of your choice and are offered in a slim envelope profile. They are provided in various finishes to meet your application requirements. .

-

Durability: When used in industrial equipment, the Industrial linear actuators are exposed to chemicals, shocks, vibrations, temperatures and pressures. In addition to these factors, the movement patterns are repeated multiple times in industrial equipment. Most times, the actuators have to withstand torsion, too. Addressing all these factors, we design most industrial linear actuators with durable material that contributes to their reliability, sustenance, and performance. All our linear motion actuators are subjected to durability testing, where they are tested to thousands of cycles at full load, followed by a safety factor and an abuse test.

-

Easy Integration: The electric linear actuators can be easily integrated into control systems using data bus communication. Our linear motion control systems are clean, energy-efficient, and non-toxic. Also, they fulfill the requirements of environmental friendly equipment.

-

Superior Control and Positioning Features: Our linear actuators are fitted with potentiometers, reed switch feedback sensors, encoders or hall sensors, which enable precise positioning, syncing, and tracking. These features help us build high-speed linear actuators and variable-speed linear actuators for different applications.

-

Excellent Customer Support: Our experienced support team comprises sales managers, application engineers, research and development engineers, and marketing, customer service, and quality experts who oversee the ordering process, from design to customization to performance optimization and implementation. All linear motion actuators displayed on the website are provided with drawings and datasheets for your reference.

These service features enable us to deliver linear actuators that assure long-term performance and maintenance-free service.

Industries and Applications Using Linear Actuators

We specialize in designing and manufacturing different types of linear actuators that are used to initiate motion in the following lightweight and heavy duty equipment and devices across industries.

-

Military: Cannon carriers, tanks, fighter planes, airplanes, helicopters, ships, robots

-

Solar Energy: Solar panels, solar trackers, solar motors, solar gearboxes, and RV solar trackers, PV panels, photovoltaic concentration equipment, concentrators –CPV, heliostats

-

Renewable Energy: Wind turbines and tidal energy machines

-

Material Handling: Product conveyor lines, baggage handling systems

-

Transportation: Commercial buses, trains, jetways, air bridges, in-ground lifting systems, drop tables, truck lifts, and lifting jacks

-

Agricultural: Farm threshers, fertilizer sprayers, tillers

-

Medical and Healthcare: Treatment chairs, dental chairs, wheelchairs, electric patient lifts, electric couches/tables, bath lifts, hospital beds, home care beds, nursing home beds, and stretchers and incubators

-

Mobility: Wheelchairs, ramps, and steps

-

Mining, Oil, and Gas: Pipe crawlers, separators, injection pumps

-

Recreational: Recreational Vehicles

-

Manufacturing and Construction: Loading trucks, towing trucks, and cranes

-

Mobile: Golf course turf care equipment, gate feeders, location switches and derailers

Services Offered

At Venture Manufacturing, we specialize in custom linear actuator design and engineering. Every application and their motion requirements are different and they must be addressed separately. We often meet these requirements through these services.

-

CAD/CAM Design Services: We have invested in CAD/CAM technologies to conceptualize and build innovative linear motion actuators to meet client expectations.

-

Prototype Creation: We provide prototype design and manufacturing services for custom and standard linear actuators. In this phase, we address design factors, including the actuator size, type of external power source – stepper motor, gear, electric, and DC.

-

Product Engineering: We understand that industrial automation solutions must be quicker to communicate better. Thus, when designing electrical linear actuators our designers take a holistic approach to product engineering. They address factors like application requirements, environmental exposure, communication requirements, programmability, type of controller/driver, and so on.

-

Actuator Manufacturing: Today, Venture Manufacturing is known as one of the leading linear electric actuator manufacturers across the US. Our advanced electric linear actuator manufacturing capabilities, combined with excellent customer service and commitment to research and development, have helped us grow.

-

Warranty Services: All our linear actuators, including electric linear actuators, are covered under a 12-month warranty. This warranty is developed to help clients protect their units against failure and improve their performance.

Custom Linear Actuator Solutions

Do you need custom linear actuators for your applications? We can help. Our team of experts will work with you to design a product that will meet your application requirements and fit your budget. Here are some general customizations that we do.

-

Customizing the length of connection wire

-

Choosing the electrical connector

-

Changing the limit switches position

-

Choosing a motor of different operating voltage

-

Choosing a lubricant for high-temperature or low-temperature applications

-

Custom mounting options

If you need a highly customized industrial linear actuator, we can modify most of our standard actuators or design a new actuator.

Important Actuator Terminologies Discussed

-

Static Load or Holding Load: The force applied to the linear motion actuator when it is not moving is known as static load.

-

Dynamic Load: This is the force applied to the linear motion actuator when it is moving or being used for push or pull. Dynamic load is also known as lifting or working load.

-

Side Loading: The force applied perpendicular to the shaft is known as side loading. This is also known as eccentric loading or radial loading. Side loading is not recommended because it can cause excessive wear and binding, which can affect the actuator’s performance.

-

Duty Cycle Rating: This is expressed as a percentage of time when the actuator works.

-

Absolute Accuracy: This is the difference between the desired and actual position. This may be affected by factors like drift, backlash, hysteresis, the measurement system, the drive’s non-linearity, and so on.

-

Bidirectional Repeatability: This refers to the accuracy with which an actuator returns to its original position after any change in the position.

-

Power Consumption: This is the maximum power consumed by the actuator when it is operated under full load.

-

Push/Pull Force: This is the force delivered by the actuator when the device is in motion. When you see the push/pull force mentioned on an actuator, it will be the maximum force offered by the actuator.

-

Push/Pull Speed: This is the speed at which the actuator will retract and extend to its maximum permissible position.

-

Stroke: This is the difference between the fully retracted length and fully extended length of the actuator. In other words, the stroke is the maximum movement the actuator can achieve.

-

Motor Speed: This is the maximum rotational speed achieved by the motor. It is expressed as RPM (revolutions per minute).

-

Motor Power: This is the maximum power consumed by the motor of the device when the electric linear actuator is operated at the full load.

Customized Actuator Products

Upload your design and customized products. Actuators can be customized to your specific needs and specifications

GET CUSTOMIZED PRODUCTS NOW

Frequently Asked Questions on Linear Actuators

-

How can I choose the right linear actuator for my application?

The choice of the right linear actuator will depend on your application requirements. If you are choosing the electric linear actuator, choose the one more force than required to move the object. Next, you need to focus on the stroke length, which is needed for the in-and-out motions. Other factors you need to address are – power consumption, type of positional feedback required, IP rating, voltage, mounting method, stroke length, force, and connectors.

-

Can I increase or decrease the speed of a linear actuator?

The speed of the actuator is controlled by factors like the voltage, gear ratio, and force. However, you can normally increase or decrease the speed of an actuator using a speed controller.

-

Do you offer lubricated lead screws? Do they need regular lubrication?

Yes, we provide lubricated lead screws; they do not normally need regular lubrication. By this, we mean that all our linear actuators, including electric linear actuators feature screws that are lubricated for a lifetime. They require no additional lubrication under regular operating conditions.

-

How can I extend the life of an industrial linear actuator?

Although our industrial linear actuators are designed to ensure long-term performance in challenging, you can extend their lifespan in the following ways:

o Minimizing the load applied

o Proper mounting

o Minimizing the instances of side loading