The stepper motor actuator is a type of actuator used in several industrial applications. It uses a DC stepper motor for rotary motion. A lead screw is attached to the motor shaft, which eventually generates a linear motion to the actuator tip if linear actuation is required. These stepper motor actuators are extensively used in applications such as robotics, agricultural equipment, medical devices, and many more. Since these types of actuators use stepper motors as the input source, the performance parameters of these linear actuators vary according to stepper motor parameters. Since stepper motor actuators are multi-application devices, the selection factors of stepper motor actuators differ according to the application. This post offers general guidelines for selecting stepper motor actuators. It basically discusses the common factors of selection, no matter what application it is used for.

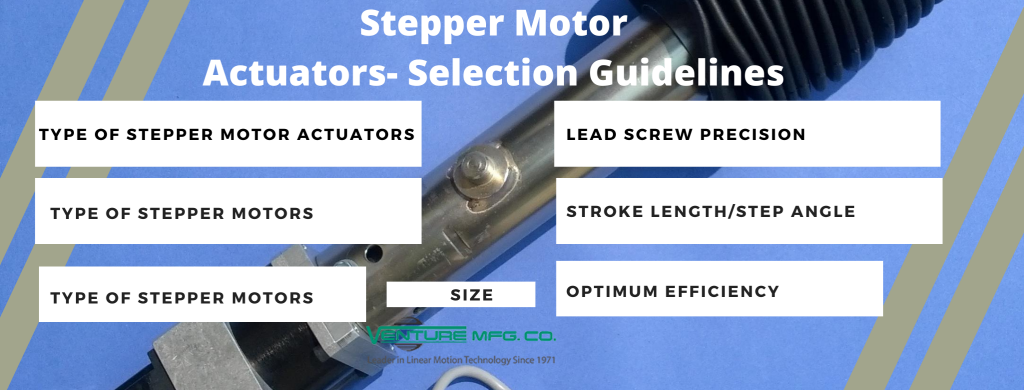

Stepper Motor Actuators- Selection Guidelines

Stepper motor actuators are used as controlled motion actuators. These actuators can be used for generating linear or rotational motion in a multitude of applications. Therefore, the type of motion becomes part of the selection criteria. However, let us discuss a couple of factors that are common considerations for the linear and rotational stepper motor actuator selection process.

-

Type of Stepper Motor Actuators:

The stepper motor actuators are differentiated based on functional abilities and performance parameters. For a specific application, a specific type of stepper actuator is suitable. Therefore, one must consider the application requirements and select a type of stepper actuator. The following are common types of stepper motor actuators you can choose from.- External shaft stepper actuator: In the external shaft stepper actuator, the lead screw is used as the motor shaft. This allows direct rotational motion which can be harnessed using a nut to enable linear motion. This type of stepper actuator is used for applications that demand frequent acceleration/deceleration, and noise reduction during operation.

- Non-captive stepper actuator: In this type of the stepper actuator, the lead screw is firmly mounted while the nut rotates. This generates pure linear motion as the guide screw does not rotate. These actuators are suitable for moderate stroke linear actuation.

- Captive stepper actuator: The captive stepper actuators are compact in design as the screw or nut is not available in the design. It features a spline shaft that restricts rotational motion and allows short-stroke linear actuation.

-

Type of Stepper Motors:

The actuators offer varying performance output depending on the type of motor used to operate it. Following are three main types of stepper motors used in stepper actuators, one must consider those during selection.- Variable-reluctant stepper motors

- Permanent magnet stepper motors

- Hybrid stepper motors

-

Torque and Input Power:

The input power to torque ratio must be considered as torque is a direct performance parameter in stepper motor actuators. Torque generates movement of lead screw therefore, lead screw travel length (Stroke) is directly proportional to the applied torque. Since the torque is generated by stepper motors, the power consumed by the motor is expected to be as little as possible for selection. -

Lead Screw Precision:

Start and stop precision of lead screw is an important selection parameter. Since applications like robotics, precisely calculated actuation is demanded, the lead screw motion must be precise. -

Stroke Length/Step Angle:

In the case of linear actuation, the required stroke length is important to be considered. The stroke length varies according to the lead pitch and driving angle of the lead screw. Different types of stepper motor actuators offer different stroke lengths. -

Optimum Efficiency:

The optimum efficiency is the collective performance of stepper motor actuators. It involves consideration of accuracy, repeatability, screw positioning, power consumption, output stroke length, and speed, etc. Also, the optimum efficiency must be high as it reduces carbon footprint. -

Size:

According to the applications, the suitable design of the stepper actuator can be chosen. For small device space applications like electronic equipment, robotics, etc, the compact design of the actuator must be chosen.

Learn more on this topic in our related blog: The Working and Advantages of Stepper Motor Actuators

Now that the selection factors of a stepper motor actuator are discussed, it is important to know that the quality of actuators can make a huge impact on the application. Therefore, you should purchase stepper motor actuators from trusted manufacturers like Venture Mfg. Co. The company has been delivering high-quality actuation solutions since 1971. They have been serving several industries like agricultural, military, miniature satellite, transportation, and many more.