Role of Electric Actuators in the Food Industry

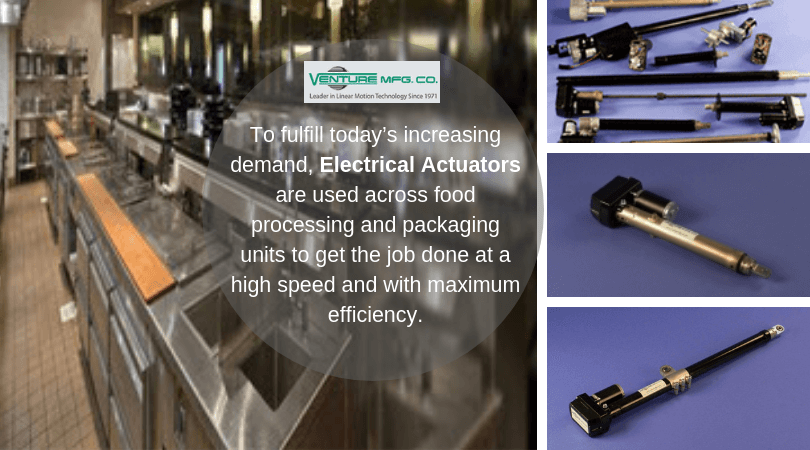

Efficient food processing and packaging operations call for high-level robust technologies that are durable, precise, and safe for food. Various food industry procedures including cutting and slicing of raw materials and filling beverages, which need to be done systematically, and without any contamination. To fulfill today’s increasing demand, electrical actuators are used across food processing and packaging units to get the job done at a high speed and with maximum efficiency. Additionally, it is crucial that these actuators are constructed from materials which do not harbor bacterial growth. Isn’t it enough? No. Would you like to know why an electric actuator plays a vital role in food processing systems? Or what are the reasons to consider electric actuators for food and beverage applications? The post discusses the benefits and application areas of electric actuators.